2017-2018 Applied Math Capstone

Supervisor: Lou Kondic

Introduction

Filtration media has changed over the years to address multitude of problems resulting from environmental, pharmaceutical, or other industrial processes. Membranes are used in nature and are now being used commonly in industrial processes to filter out undesired solute from suspensions, etc. These membranes typically lose efficiency over a period of time because of plugging, degradation, and is generally referred to as membrane fouling. Microfiltration processes which use protein solutions tend to foul the membranes despite their small size compared to the pore cross-section [1].

Tracey and Davis [2] state fouling occurs at the mouths of the pore, slowly closing off the pore entrance areas while allowing complete transmission of the protein for a period of time. Eventually, the pores become so constricted that protein transmission decreases and a layer of rejected protein forms on the external membrane surface. On the other hand, Nakamura and Matsumoto developed a mathematical model of internal fouling in protein microfiltration [3], and the flux decline is modelled by a pore narrowing model, but neglects the fact of cake build up.

The focus of our study is to develop specifications for the optimal pore orientation in the membrane media that resists fouling. As part of this study, we used a mathematical model to simulate fouling including adsorption, and cake layer formation as followed by Tracey and Davis. We modified the pore orientation to generate an optimum orientation at which the resistance to fouling was substantial.

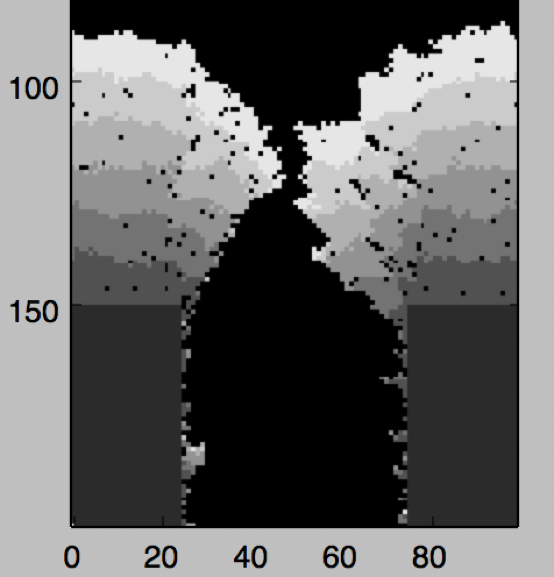

Figure 1: Example of aggregate obtained with a membrane sticking parameter of spm = 0.15 and an aggregate sticking parameter spa=0.15

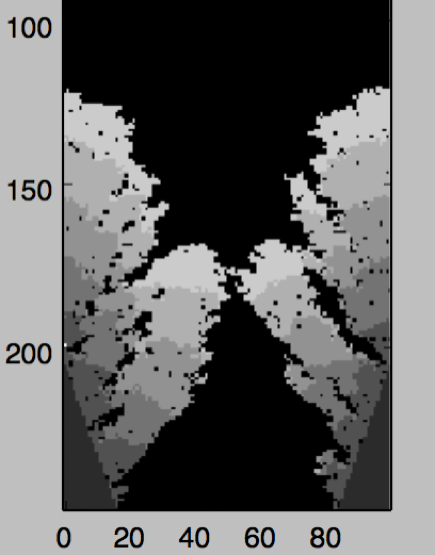

Figure 2: Example of aggregate obtained with the membrane at an angle of 20 degrees, sticking parameter spm = spa = 0.15

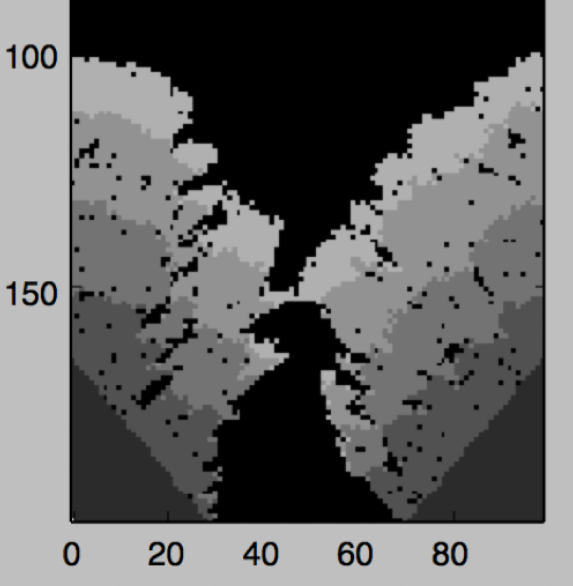

Figure 3: Example of aggregate obtained with the membrane at an angle of 40 degrees, sticking parameter spm = spa = 0.15