Membrane filters - essentially, thin sheets of porous material, which act to remove certain particles suspended in a fluid that

passes through the medium - are in widespread industrial use, and represent a multi-billion dollar industry in the US alone.

Major multinational companies manufacture a huge number of membrane-based filtration products, and maintain a keen interest in

improving and optimizing their filters. Membrane filtration is used in applications as diverse as water purification; treatment

of radioactive sludge; various purification processes in the biotech industry; and the cleaning of air and other gases. While

the underlying applications and the details of the filtration may vary dramatically (gas vs liquid filtration; small vs large

particle removal; slow vs fast throughput; rigid vs deformable particles), the broad engineering challenge of efficient filtration

is the same: to achieve finely-controlled separation at low power consumption.

The desired separation control is to remove only those particles in a certain size range from the input flow (often referred to

as "feed" or "challenge solution"); and the obvious resolution to the engineering challenge would appear to be: use the largest

pore size and void fraction consistent with the separation requirement. However, these membrane characteristics (and hence the

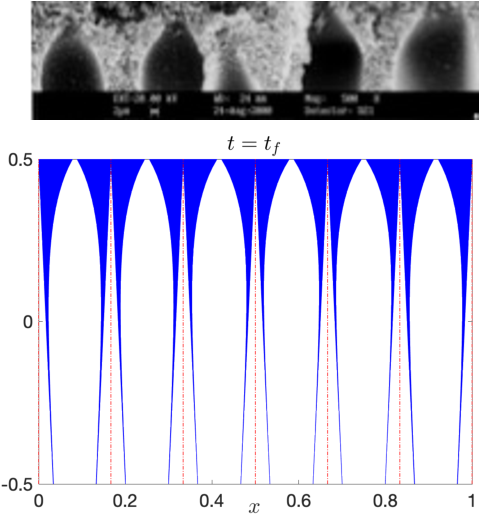

filter's behavior and performance) are far from constant over its lifetime: the particles removed from the feed are deposited within

and on the membrane filter, fouling it and degrading the performance over time. The processes by which this fouling occurs are

complex, and depend strongly on several factors, including: the internal structure of the membrane; the flow dynamics of the feed

solution; and the type of particles in the feed (the shape, size, and chemistry affects how they are removed by the membrane).

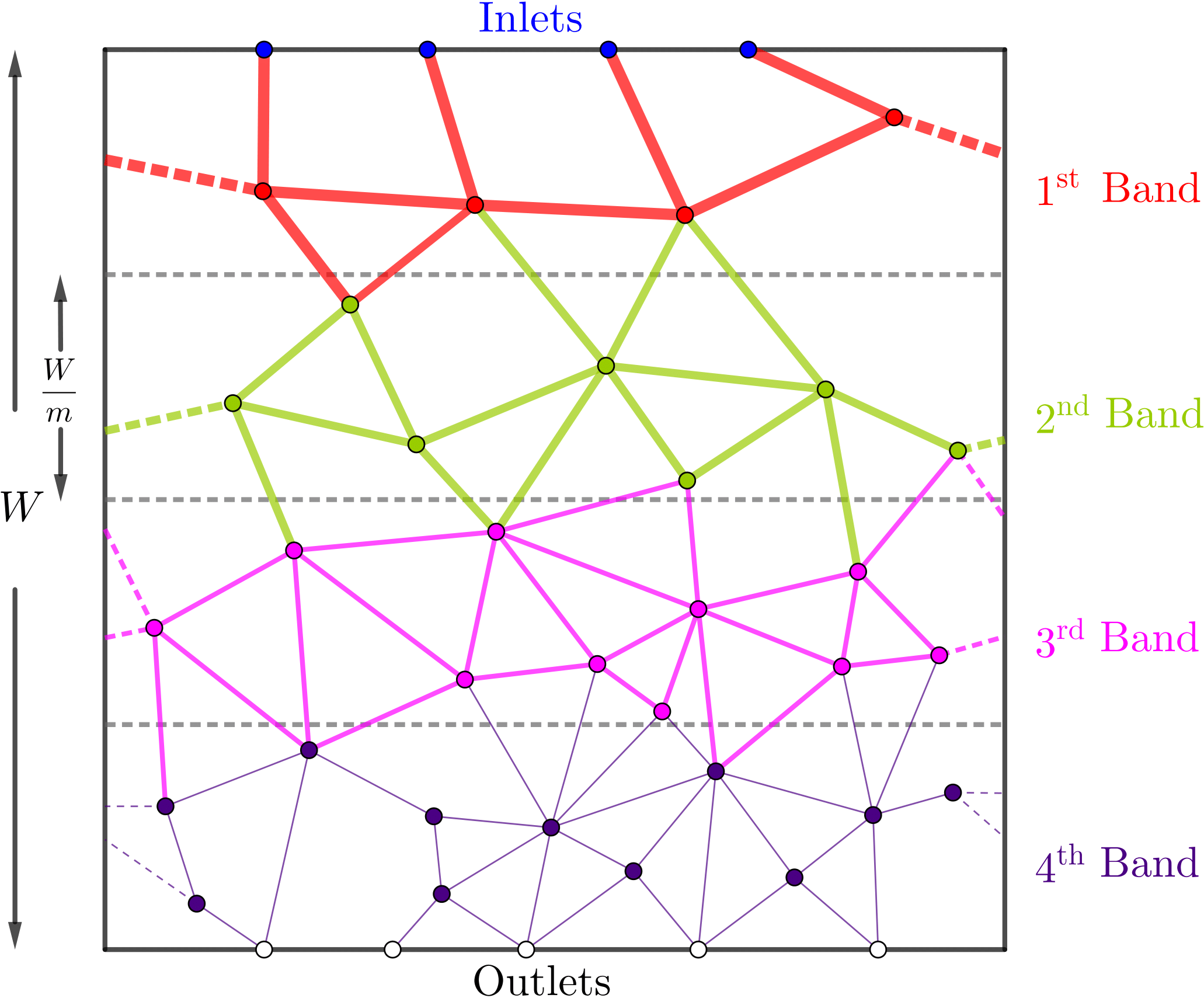

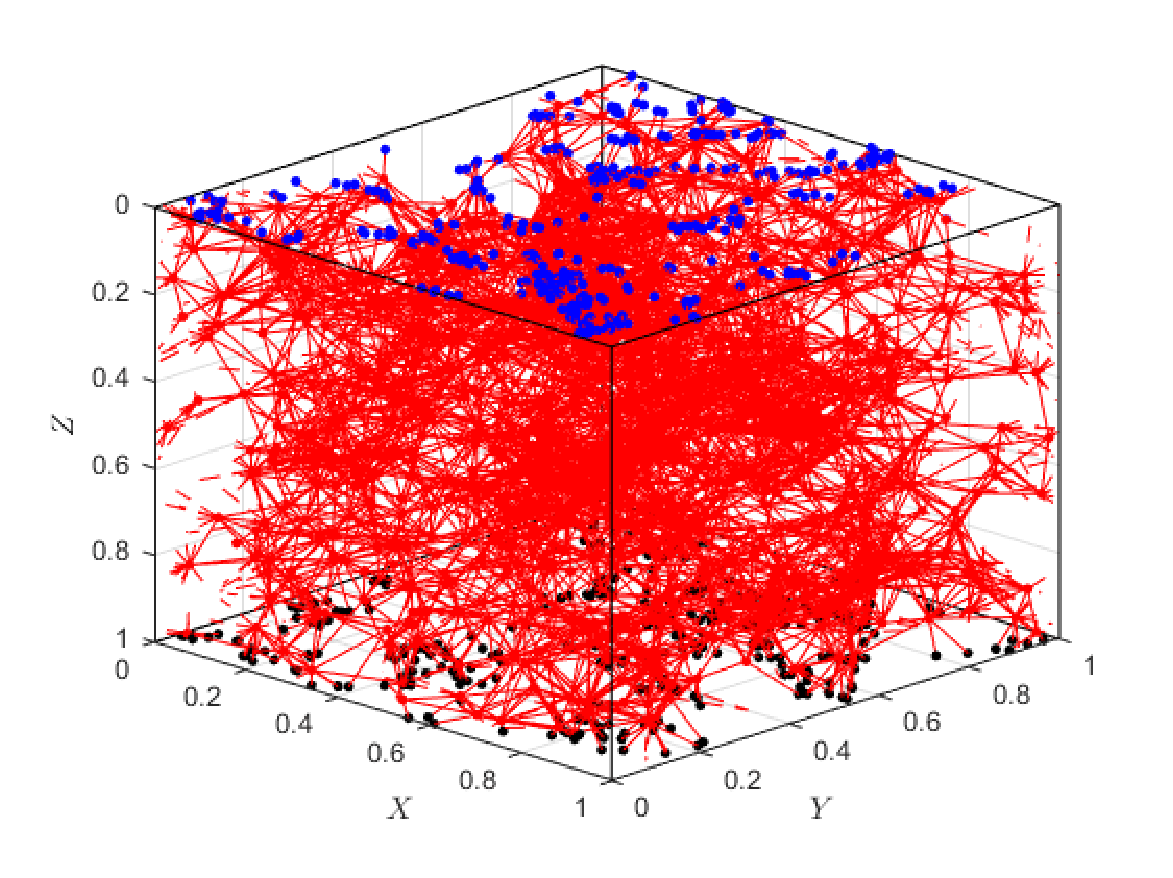

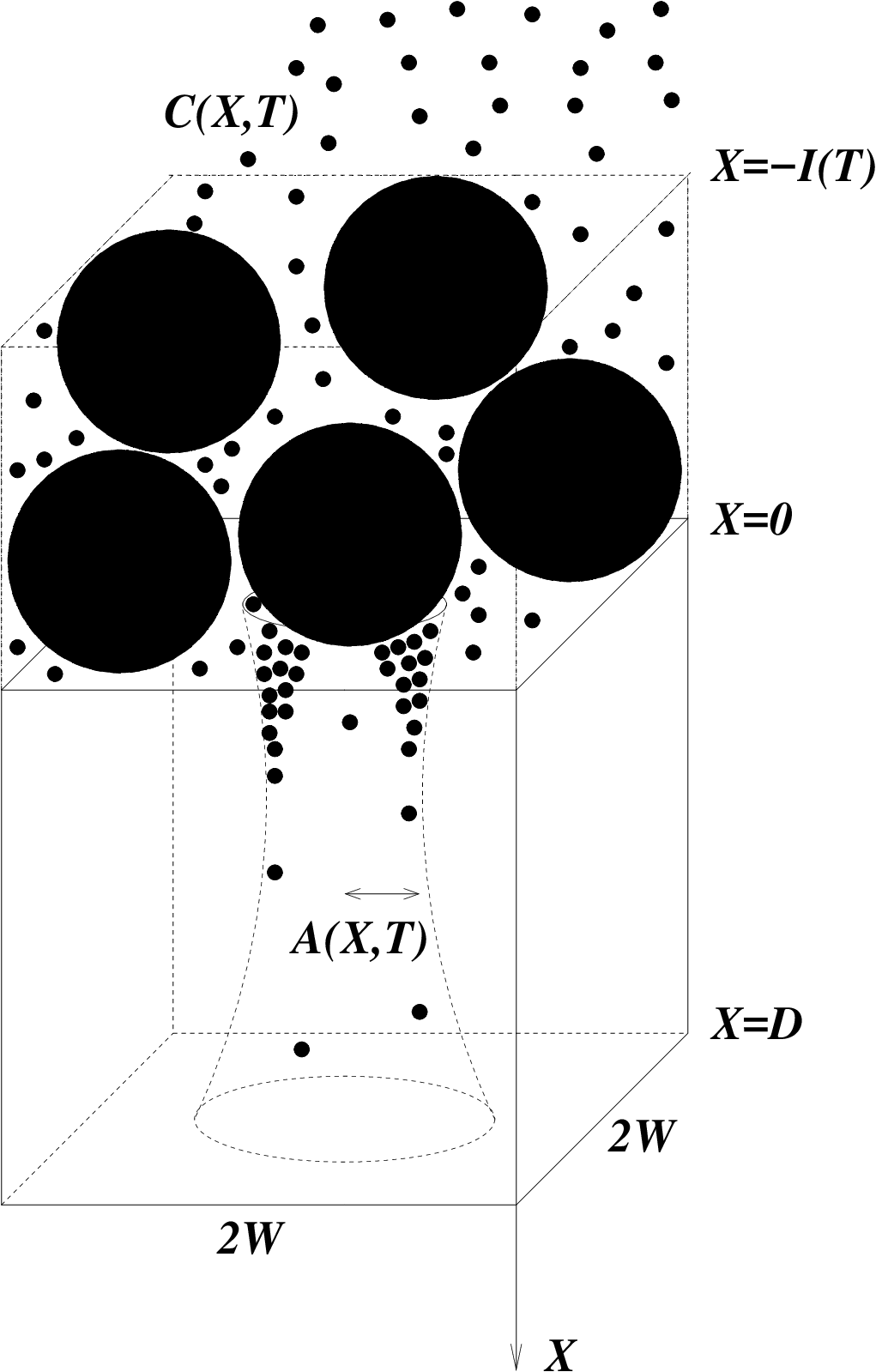

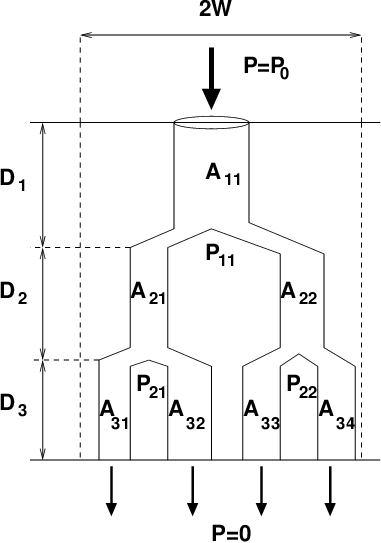

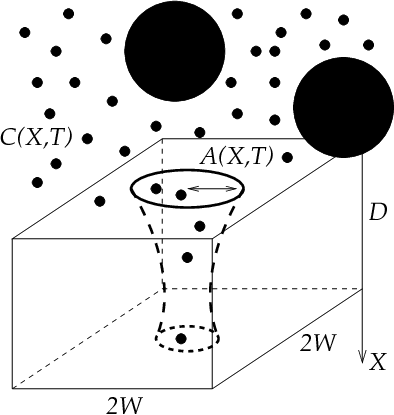

Our work is concerned with the development, analysis and computational simulation of new models governing membrane filtration, in two situations of widespread practical interest: (i) Flow and fouling within pleated filter cartridges; and (ii) Fouling models for internally heterogeneous membranes. In both scenarios we are building models that account for an arbitrary particle size distribution within the feed solution, and account also for a distribution of membrane pore sizes. First-principles theoretical studies of these scenarios should be of interest to those carrying out fundamental experimental research on such systems, as well as to those seeking to extend the scope of current applications and improve on manufacturing processes.

This project has also served as a base for a joint research project with the group of local high school students from Middlesex County Academy for Science, Mathematics and Engineering Technologies in 2019: Anay Badiani, Sid Kunisetty, Justin Lee, and Heer Patel, leading to the research report linked here.

Our recent publications in this area, listed below, give an indication of projects completed to date. This work is supported by the National Science Foundation under grants DMS-1261596 and DMS-1615719.